The ESP32 Mini uses a CP2104 UART module to drive the USB port. The CP2104 is configured in self-powered mode, which means that even if nothing is plugged into the USB port and the board is powered by a 3.3V source, it is still drawing ~100uA of current. I wanted to see the effect of removing this module on the power consumption of my test circuit.

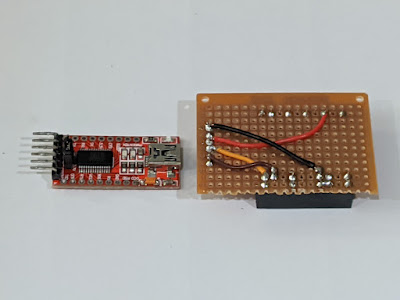

Removing the UART module means losing access to the USB port. However, I should still be able to program it using a standard FTDI programmer, which I wanted to verify. So I took out the same FTDI programmer that was used for programming the ESP8266, and built a custom holder for the ESP32 Mini.

I started with the same connections as used with the ESP8266:

- ESP32 VIN <-> FTDI 3.3V

- ESP32 GND <-> FTDI GND

- ESP32 TX <-> FTDI RX

- ESP32 RX <-> FTDI TX

However, I could not get it to work. After some fiddling around, I discovered I could only get it to work by connecting RX - RX and TX - TX. Not sure why.

But now I am confident I can still program the board without its USB, so I proceed to remove the CP2104 module (marked in red) with a hot air gun.

After removing the UART module, I verified that the board was still working by uploading the code here, and plugging it into the test circuit. Sure enough, the clock started ticking. It worked!

Note: with such small current, the power used by the LTC4150 itself becomes very important. From the datasheet, at 2.7V, its typical power usage is 80uA, with a max of 100uA. With a 10Kohm passive load, I got a reading of 430uA. Substracting 90uA from the reading gives me 340uA, which compares well with the multimeter reading of 326uA.

Using a 1ohm sense resistor means I can no longer use WiFi in my test code. The 500mA current drawn will cause the board to brown out and reset.

So finally, with the UART module removed, the current draw is 650uA - 90uA = 560uA, or ~0.6mA. This is a hugely improvement over the 1.13mA that I measured previously with the UART module intact.

So it looks like I am going to go ahead and create the full ESPCLOCK code with this setup.

Comments

Post a Comment